BASIC OF WARE WASHING

Establish standard policies for the proper procedure for washing and sanitizing equipment f & b prouduk and services to reduce microbiological contamination and chemical contamination to prevent proper cleaning concentration and contact time in the process..

Establish standard policies for the proper procedure for washing and sanitizing equipment f & b prouduk and services to reduce microbiological contamination and chemical contamination to prevent proper cleaning concentration and contact time in the process..1. MANUAL POT WASHING PROCEDURE

• all utensils to be washed must be no food residue

• all utensils to be washed must organized

• washing stainless utensils and chinaware must separate

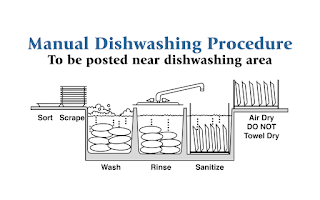

• manual washing process must available Three Compartment Sinks to wash, rinse, and sanitizing

• all the washing process must pass through three steps of wash, rinse, and sanitizing

Washing and sanitizing steps

• remove leftover food from equipment before washing procedure

• washing dirty utensils, with of soap solution temperature 45C - 55C

• rinse utensils has been washed with water temperature 55C - 65C

• sanitation utensils that has been rinsed with a sanitizing solution temperature 25C

DISHWASHING MACHINE PROCEDURE

DISHWASHING MACHINE PROCEDURE• dishwashing machine only to wash chinaware, glassware, and cutleries

• all utensils to be washed must organized and deco system

Washing and sanitizing steps

• Check dishwashing cleanliness inside machine tray, water tank, water nozzle and reel machine must be clean before using and cleaning Body Machine.

• Prepare Rack Glasses, Plates and Cutleries for Washing. Wet and Dry Garbage Bin and Clean Transportation Trolley for Glass, Plates and Cutleries.

• On Machine, Fill water and Check correct function of machine at the beginning of each shift and record the monitored temperature into ‘Dishwashing and Glass washing Units - Routine Temperature Control

• Wash temperature 55C – 65C

• Final rinse temperature 82C – 86C (thermal disinfecting) but never exceeding 90˚C, therefore all utensils will receive the hot treatment > 71C.

• It is recommended to test with irreversible thermo-sensitive stripes each morning, result to be recorded / the strip to attach on the ‘Dishwashing and Glass washing Checklist - Routine Temperature Control (BFSMS-3-013)’.

• Should water temperature be < 82C, manual sanitizing would need to be carried out.

• Change water waste tank every 2 hours or more frequent as required.

• Sorting and Separate handling of clean and dirty items.

• Sanitize hands before handling clean items.

• Use clean towel to polish, only when absolutely necessary.

Menetapkan kebijakan standar untuk prosedur yang tepat untuk peralatan pencuci dan sanitasi futan dan prouduk dan layanan untuk mengurangi kontaminasi mikrobiologis dan kontaminasi kimia untuk mencegah konsentrasi pembersihan dan kontak yang tepat dalam prosesnya.

1. PROSEDUR WASHING

• semua peralatan yang harus dicuci harus tidak ada residu makanan

• semua peralatan yang harus dicuci harus diatur

• mencuci peralatan stainless dan barang pecah belah harus terpisah

• Proses mencuci manual harus tersedia Tiga Tempat Tidur Kompartemen untuk mencuci, membilas, dan menyucikan

• semua proses pencucian harus melewati tiga tahap cuci, bilas, dan sanitasi

Langkah pencucian dan sanitasi

• buang sisa makanan dari peralatan sebelum prosedur pencucian

• mencuci peralatan kotor, dengan suhu larutan sabun 45C - 55C

• Peralatan bilas telah dicuci dengan suhu air 55C - 65C

• Peralatan sanitasi yang telah dibilas dengan larutan pembersih 25 ° C

2. PROSEDUR MESIN DISHWASHING

• Mesin pencuci piring hanya untuk mencuci barang pecah belah, barang pecah belah, dan alat pemotong

• Semua peralatan yang harus dicuci harus diatur dan sistem deco

Langkah pencucian dan sanitasi

• Periksa kebersihan pencuci piring di dalam baki mesin, tangki air, nosel air dan mesin reel harus bersih sebelum menggunakan dan membersihkan Mesin Tubuh.

• Siapkan Kacamata Rack, Pelat dan Cutler untuk Pencucian. Bin Sampah Basah dan Kering dan Trolley Transportasi Bersih untuk Kaca, Pelat dan Cutler.

• Pada Mesin, Isi air dan Periksa fungsi mesin yang benar pada awal setiap shift dan catat suhu yang dipantau ke 'Dishwashing and Glass Washing Unit - Kontrol Suhu Rutin

• Cuci suhu 55C - 65C

• Suhu bilasan akhir 82C - 86C (desinfektan termal) namun tidak melebihi 90 ° C, oleh karena itu semua peralatan akan menerima perawatan panas> 71C.

• Dianjurkan untuk menguji dengan garis termo-sensitif ireversibel setiap pagi, hasilnya akan dicatat / strip untuk dilampirkan pada checklist Cuci Piring dan Kaca - Kontrol Suhu Rutin (BFSMS-3-013) '.

• Jika suhu air menjadi <82C, penyiapan manual perlu dilakukan.

• Ubah tangki pembuangan air setiap 2 jam atau lebih sering sesuai kebutuhan.

• Menyortir dan Memisahkan penanganan barang bersih dan kotor.

• Sanitasi tangan sebelum menangani barang bersih.

• Gunakan handuk bersih untuk memoles, hanya bila benar-benar diperlukan.

Komentar

Posting Komentar